<track id="kgge3"></track>

<table id="kgge3"></table>

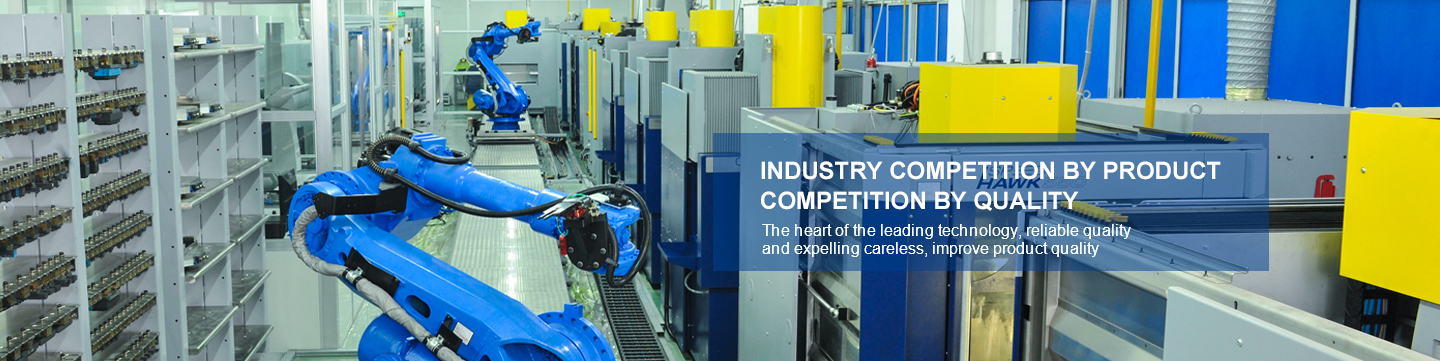

Car milling integrated flexible production line combined with milling process. This production line adopts the ship 20 kg of six degrees of freedom, independent research and development of intelligent industrial robots and control system, can realize the presence of unmanned automatic processing. Production line is mainly composed of a machining center, a CNC lathe and a six axis robot, with guide rail, rack, loading and unloading station, cleaning stations, fences and other auxiliary parts, and through the unit management system unified control.

Car milling integrated flexible production line combined with milling process. This production line adopts the ship 20 kg of six degrees of freedom, independent research and development of intelligent industrial robots and control system, can realize the presence of unmanned automatic processing. Production line is mainly composed of a machining center, a CNC lathe and a six axis robot, with guide rail, rack, loading and unloading station, cleaning stations, fences and other auxiliary parts, and through the unit management system unified control.