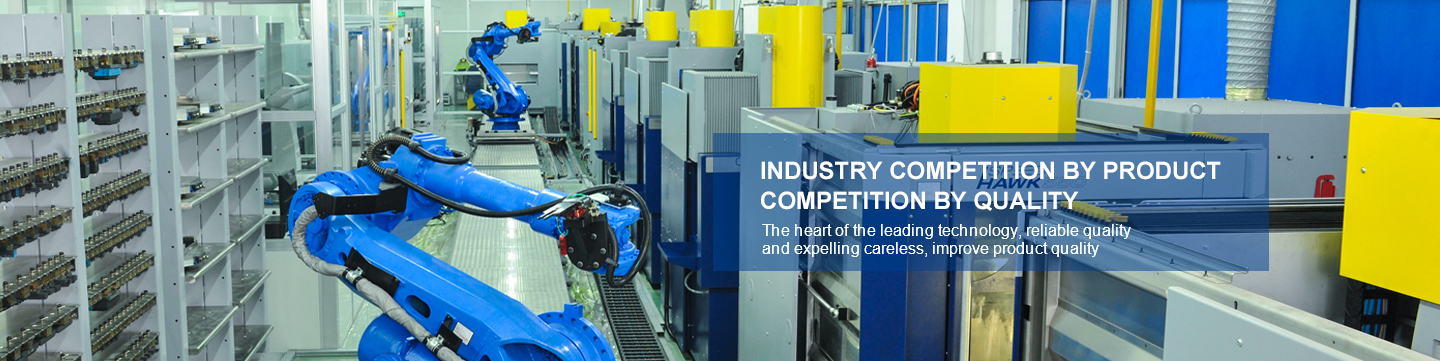

Automatic electrode flexible production line

Product Features:

Flexible production line automation electrode by four Fagor system three-axis electrode processing center, one 20 kg six degrees of freedom, industrial robot, 1 of article 15 meters of linear guide, 80 location library the workpiece and the security fence, security door and related peripheral equipment. Production line is controlled by a set of flexible production management system, implementation: the staff use PC after distribution processing tasks, the production department management system according to robots and CNC automatic scheduling task information, to realize automatic robot for CNC automatic up-down and CNC machining, under the condition of a single intervention to complete the function of automatic production.

Product description

System Components

Flexible production line automation electrode by four Fagor system three-axis electrode processing center, one 20 kg six degrees of freedom, industrial robot, 1 of article 15 meters of linear guide, 80 location library the workpiece and the security fence, security door and related peripheral equipment. Production line is controlled by a set of flexible production management system, implementation: the staff use PC after distribution processing tasks, the production department management system according to robots and CNC automatic scheduling task information, to realize automatic robot for CNC automatic up-down and CNC machining, under the condition of a single intervention to complete the function of automatic production.

Equipment use: used to implement the graphite electrode processing automation

Class 3 continuous production equipment using divisions: 7 days/week

Equipment using the environment:

Temperature: Max. 50 ° C relative humidity: Max. 95%

Energy:

Power supply: three-phase ac 380 v, 220 v communication

Compressed air: 0.6 Mpa to 0.7 Mpa

Production line control system, is the core of realizing automation production. With adding production tasks, the production data management, material warehouse management, equipment management, production scheduling, production safety management, and other functions. For automatic production line control system, as the brain controls the whole production line operation.

Processing center, processing center can use FAGOR, FANUC system of machining center, etc. According to the practical production requirements.

Wheel robot: a great JLRB20 JLRB50 or other type of six degrees of freedom, industrial robot, can undertake choosing according to the practical production requirements.

Material warehouse: to hold for processing and processing of materials, adopts the principle of book posture stereoscopic warehouse, warehouse location, size according to the actual need to carry on the design.

Convenient loading and unloading station: operator, loading and unloading material can be installed according to the actual demand to choose or not.

Online cleaning equipment, testing equipment: according to the actual demand for installation.