|

Greatoo Polishing Technology Center

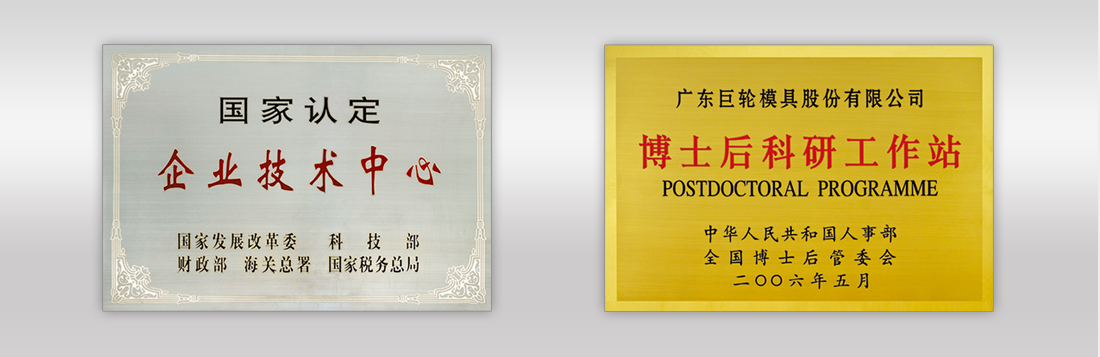

Greatoo Intelligent insists on taking science and technology innovation as dynamic and integrating inside and outside corporation resources from strategic height, improves innovation mechanism and organizational structure, builds a beneficial environment to innovation, and encourages industrialization, commercialization and revenue maximization of technical innovation achievements, in order to enhance enterprise core competitive power constantly. Jointly recognized by National Development and Reform Commission, the Ministry of Finance, the Ministry of Science and Technology, State Administration of Taxation and the General Administration of Customs, Greatoo set up “National-certified Enterprise Technology Center”. With ratification of Guangdong Provincial Department of Science and Technology, Greatoo organized Guangdong Provincial Tire Mold Engineering Technology Research Center, specializing in researching and developing of automobile tire mold and rubber machinery. Authorized by Ministry of Human Resources and Social Security of the People’s Republic of China, the company set up post-doctoral scientific research station. We also work together with Guangdong University of Technology on founding “Production-learning-researching base of tire mold digitization engineering”, and cooperate with the Hong Kong Polytechnic University on building “Greatoo Tire Mold Surface Polishing Technology Center”.

|